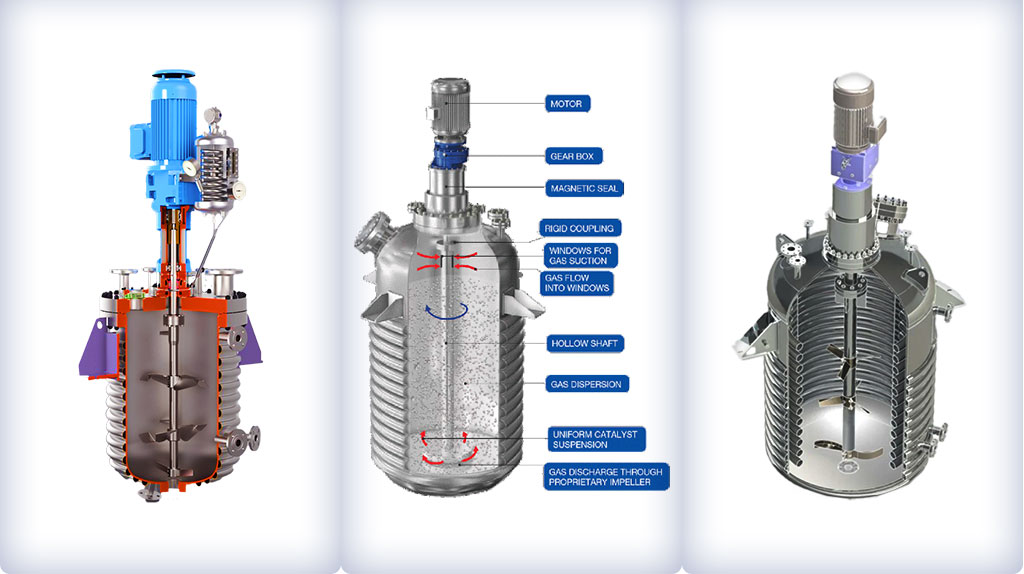

SAR Contempflo offers a tailored solution to meet your needs for the hydrogenation process. Being at the forefront of developing an extensive array of agitation systems, we recognize the critical role of different types of agitators. Comprehending the reactants involved in these processes is crucial, but so is having a practical understanding of the process, where our expertise lies.

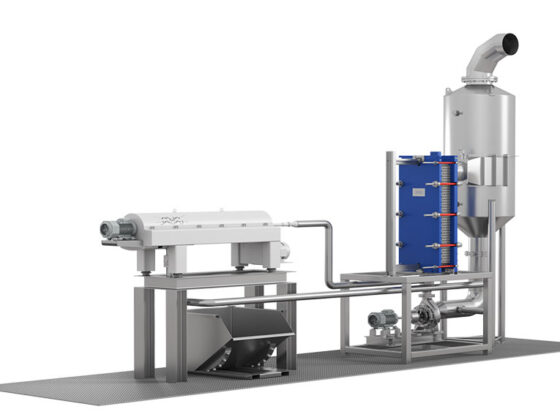

Complete Process View

- Maximum gas dispersal

- Maximum mass transfer

- Gas Remixing

- Suspension of Catalyst

- Heat Transfer

SPECIFICATIONS

- Capacity: Upto 20 KL

- Pressure: Upto 100 Bar

- Temperature: Upto 300°C

- Seal: Magnetic / Mechanical

- Materials Of Construction: SS-304, SS-316, Hastelloy, Titanium & all Exotic Metals with or Without Bonded metal Can take up Hydrogenation Plant designs as per latest PESO norms

- Total Automation with PLC SCADA / DCS

APPLICATION

- Pharmaceutical synthesis: Used in the production of pharmaceutical intermediates and active pharmaceutical ingredients (APIs).

- Food processing: Facilitates the hydrogenation of edible oils for the production of margarine, shortenings, and other food products.

- Petrochemical refining: Essential in refining processes to modify the properties of hydrocarbons.

- Fine chemical production: Enables the synthesis of specialty chemicals for various industrial applications.

- Polymerization: Utilized in the production of polymers and plastics.

- Agricultural chemicals: Important for the synthesis of agrochemicals such as pesticides and herbicides

FEATURES

- Catalytic hydrogenation: Utilizes catalysts to facilitate the addition of hydrogen atoms to unsaturated compounds.

- High-pressure vessel: Contains the reaction environment under controlled conditions of temperature and pressure.

- Versatility: Can be used with a variety of feedstocks and catalysts for diverse applications.

- Precision control: Allows for precise control over reaction parameters such as temperature, pressure, and hydrogen flow rate.

- Efficient and selective: Enables high conversion rates and selectivity, minimizing byproducts and maximizing desired products.

- Scalability: Available in various sizes to accommodate different production scales, from laboratory to industrial-scale operations.

- Safety features: Equipped with safety measures to ensure the secure handling of flammable hydrogen gas under pressure.

- Automation: Some models feature automation capabilities for enhanced process control and efficiency.